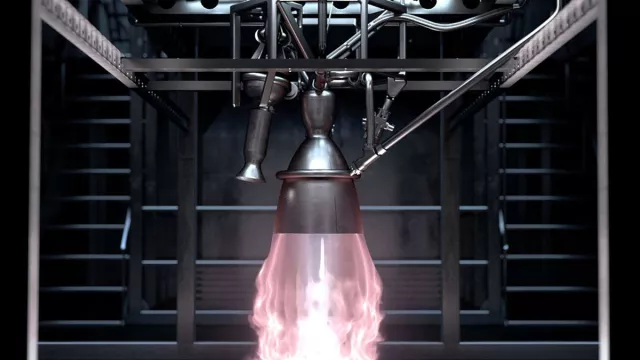

Prometheus is a very-low-cost engine that will run on methane, marking a significant break with today’s technologies. The first hot-fire tests were conducted in 2022 and the engine is scheduled to enter service by 2030.

Key information

| Mission | Develop a low-cost reusable engine for Europe’s future space launchers, powered by methane, parts manufactured by 3D printing |

|---|---|

| Domain | Space transportation |

| Start date | First hot-fire test on 30 September 2022 |

| Partners | DLR, ESA, ArianeGroup, GKN Aerospace, SAB Aerospace |

| Where | Europe’s future launchers, covering the full range from micro-launchers to a new version of Ariane |

| Lifetime | Indefinite |

| Status | In development |

Key figures

- 5 times that engine can be re-used

- 120 tonnes maximum thrust

- 10: cost-reduction factor

- 50 engines produced per year

Key milestones

- 2026: Prometheus Mark-2 validation campaign at PF50 in Vernon

- 2025: Prometheus Mark-2 demonstration campaign at DLR’s P5 in Lampoldhausen

- 2024-2025: Prometheus Mark-1 demonstration campaign at DLR’s P5 in Lampoldhausen

- 22 June 2023: First full firing of M1 article

- 30 September 2022: First hot-fire test

- December 2016: ESA adopts project

- 2015: Project initiated by CNES and ArianeGroup

Project in brief

Europe’s Ariane launcher has been powered since 1996 by the Vulcain engine. By 2030, a new engine called Prometheus (Precursor Reusable Oxygen METHane cost Effective propUlsion System) will be picking up the baton. Reusable up to five times and capable of delivering variable thrust up to 120 tonnes, Prometheus will burn oxygen and methane in place of oxygen and hydrogen.

Among methane’s many advantages as a rocket fuel, it is cheaper, easier to handle and remains liquid at almost the same temperature as oxygen. Six times denser than hydrogen, methane will also enable more-compact rocket stages, making them easier to recover for reuse. CNES is also looking at producing methane from biomass at the Guiana Space Centre.

From an economic perspective, Prometheus is aiming to reduce production costs tenfold with respect to the Vulcain engine—which has a unit cost of €1 million—thanks to a different architecture, extensive use of 3D printing and a production rate of 50 engines per year. From a schedule perspective, the goal is to equip the lower (with the Themis demonstrator) and upper stages of Europe’s future range of launchers—from micro-launchers to a new version of Ariane—by 2030.

CNES’s role

Prometheus was conceived and designed by CNES and ArianeGroup between 2015 and 2017. Responsibility for the programme was handed over to the European Space Agency (ESA) at the Ministerial Conference in Lucerne in December 2016. ESA has tasked ArianeGroup with developing Prometheus and CNES is supporting the agency on project oversight, notably as Project Technical Officer on the joint ESA/CNES team. CNES is also participating as industry partner to pool the best talents and experience with a view to pushing the limits of disruptive innovation for the Prometheus project.

The first engine tests are being conducted at the Vernon facility on the THEMIS-1G test platform developed with funding from the government stimulus plan and under a CNES contract. The first full hot-fire test of the first M1 engine was completed on 22 June 2023.

Contacts

Project Leader

Amaya Espinosa

E-mail: amaya.espinosa at cnes.fr

Head of Space Transportation Strategy

Philippe Pujès

E-mail: philippe.pujes at cnes.fr