Q&A with…

- Vincent Favier, BEAP test manager at CNES

- Éric Robert, ESA/CNES integrated team technical officer

What is the future P160C engine set to power both Ariane 6 and Vega?

Vincent Favier: The P160C is planned to start operating on the European Ariane 6 and Vega-C launchers during the course of 2026, and subsequently on the future Vega-E launcher. It’s expected to improve their performance by around 10%, for the same cost. It’ll afford the lift capacity for more or heavier satellites, or to boost them further into space. One of its aims is to provide the capability to launch constellations of satellites.

Éric Robert: The P160C will be employed as a booster on an enhanced Block 2 variant of Ariane 6, and as a first stage on the Vega-C light launcher and the future Vega-E. It’ll replace the current P120C engine that performs the same functions on Europe’s two launchers. The P160C is a metre longer than the P120C, and can hold 14 extra tonnes of solid propellant*, enough to keep running in flight for more than two minutes.

* Solid rocket propellant is a composite substance in which the fuel and oxidizer are already mixed together; it has the same consistency as a pencil eraser.

Engine or booster: what’s the difference?

Boosters are mounted on the side of a launcher. They were originally termed “additional side boosters”, but on Ariane 5 and 6 they deliver 90% of the launcher’s thrust off the pad. Ariane 6 offers two variants, one with two boosters (A62) and one with four (A64). The current booster model is the P120C. While a booster is indeed a rocket engine, the reverse isn’t always true. The P120C and P160C are employed as boosters on Ariane 6, but as a rocket stage on Vega-C.

What does a rocket engine test involve? And how do we test an engine without it lifting off the launch pad?

V. F.: The test performed on 24 April by CNES consisted in firing a qualification model of the engine for 2 minutes and 20 seconds. A hot-fire test like this allows us to collect data that we then compare with expected values to validate the engine’s performance, notably its thrust performance.

E. R.: For a hot-fire test, the engine is attached in a vertical position to the test stand to replicate the real launch configuration as closely as possible. When it ignites, it lifts a few centimetres off the ground and is then held down by the test stand. A system measures the real pressure and thrust, along with 600 pressure, temperature, structural deformation and other readings.

During the test, gases are expelled through the nozzle and can be steered using actuators: that’s how we check that we’ll be able to adjust the direction of thrust in flight. This thrust-vectoring system is also tested.

V. F.: Once the test is complete, it’s time to analyse the results. Teams sift through all of the readings during what we call “level zero” test analysis. This phase looks at the readings acquired during the test and answers crucial questions for qualification, like: Are the thrust and the post-firing mass right? Are the vibrations, temperatures, nozzle behaviour and steering as expected? In short, are all the forces exerted on the test specimen compliant?

Why P160C?

The ‘P’ in the booster’s name stands for ‘powder’ (although these days solid rocket propellant is used rather than gunpowder). The number 160 represents 160 tonnes of propellant (the exact mass is in fact 156 tonnes). And the ‘C’ stands for Common, as the engine is used both on Ariane 6 and Vega-C.

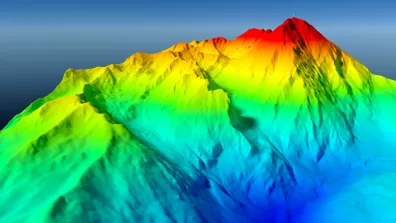

What makes the BEAP test stand where the test was conducted unlike any other?

V. F.: The BEAP* solid booster test stand is the only large-scale test stand operated by CNES, on behalf of the European Space Agency (ESA). It’s located at the Guiana Space Centre in Kourou. It’s actually a quite modular and scalable test stand. We’ve tested Ariane 5’s big boosters, the P80 booster, the first stage of Vega and the P120C booster on it. Another feature is that it’s one of few test stands in the world that supports vertical firing tests, i.e., in a configuration close to a real launch.

* Banc d’Essai des Accélérateurs à Poudre in French

E. R.: It comprises a 50-metre-high tower for full-scale testing of boosters for Europe’s launchers. It also has a flame trench to channel away exhaust gases. And it’s connected to a test control station several hundred metres from the tower.

V. F.: The BEAP is only used during test campaigns. As a result, we draft in people from the teams working routinely on other missions at the Guiana Space Centre (for example, on Ariane 6’s ELA-4 launch pad qualifying the four-booster model, or on micro-launchers). The rest of the time, it remains “on standby”.

Controlled environmental impact

Like a real launch, a hot-fire test on the BEAP is subject to weather conditions, i.e., wind speed at the launch pad and aloft, precipitation (no rain within a window of one hour after firing). These very tight constraints limit dispersion of pollutants in the environment. For each test or launch, CNES applies a plan for measuring the quality of the air, water, fauna and flora in order to gauge its environmental impact. There are 30 fixed and mobile sensors deployed around the BEAP throughout the test, some as far away as Kourou and Sinnamary.